3D

printing technologies have been transforming the healthcare industry

since the 1990s. But the demand for and adoption of 3D printing

technology by healthcare companies has been increasing steadily in

recent years. Most healthcare companies these days use 3D printers to

produce three-dimensional models that facilitate the personalization of

treatment and minimization of operative risks.

According to a report published by Data Bridge Market Research,

“Global healthcare 3D printing market is registering a healthy CAGR of

19.22% in the forecast period of 2019-2026. This rise in the market can

be attributed to the increased demand for specific 3D printing,

increasing applications for medical treatment and government investments

in 3D printing project.”

The

forecast depicts the increase in 3D printing applications in medicine

and surgery. Many medical professionals use 3D-printed devices and

instruments. Likewise, many surgeons use 3D printing technologies to

preplan and perform surgical procedures accurately. We can assess the

significance of 3D printing for the healthcare industry based on some of the innovative use cases on medical 3D printing technologies.

8 Innovative 3D Printing Applications in Medicine and Surgery

1) Bioprinting Organs and Tissue Structures

According to Science.org.au, “Bioprinting can produce living tissue, bone, blood vessels and, potentially, whole organs for use in medical procedures, training and testing.” Bioprinting is often described as an extension of 3D printers. The surgeons use advanced 3D printers to generate patient-specific tissue-like structures using bioinks as the primary material. The 3D-printed tissue-like structures are personalized for a patient with optimal accuracy and precision. Many healthcare companies have been investing in research to create fully functional organs for patients with grave organ failure by leveraging advanced 3D printing technologies.

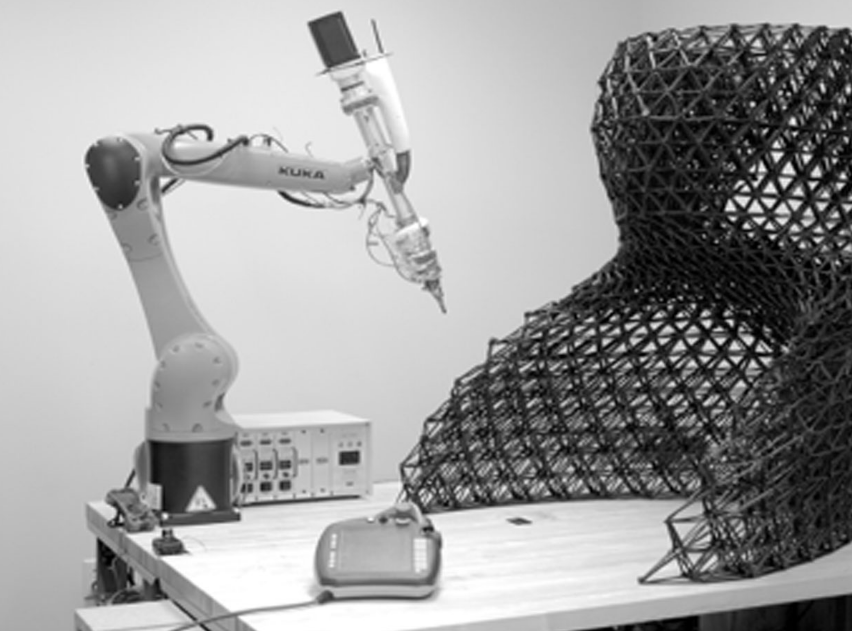

2) Producing New Surgical Instruments

Like other enterprises, healthcare companies use 3D printing services to facilitate rapid prototyping. 3D printing makes it easier for medical device manufacturers to create and test prototypes of new devices without incurring huge expenses. At the same time, 3D printing technologies help surgeons and physicians to communicate design ideas clearly and unambiguously. Researchers have been using combining different 3D printing technologies and materials to produce new medical devices and surgical instruments regularly. Also, many companies these days use 3D printers to produce instruments and devices in a short amount of time.

3) Creating Medical Phantoms

According to Radiopaedia.org, "A phantom or imaging phantom is a highly specialized object utilized in medical imaging for quality control, equipment calibration, dosimetry and education." Researchers and physicians these days use phantoms for training, testing, and research purposes to eliminate the need to use a living subject.

Advanced 3D printing technologies make it easier for researchers to create medial phantoms that replicate patient-specific organs accurately in various medical settings. Doctors have already used 3D printing to create phantoms of kidneys and artillery before operations. The 3D-printed phantoms are expected to transform organ transplant procedures in the future.

4) Patient-Specific Drug Delivery

Often patients have to consume multiple pills according to the drug dosage prescribed by doctors. They have to purchase additional pills to adhere to drug dosage. 3D printing technologies create opportunities for pharmaceutical companies to transform and personalize drug delivery completely.

A pharmaceutical company can leverage 3D printers to produce and deliver dosage for patients individually. Also, they can deliver drugs on demand according to the changes in a patient’s dosage profile. Many healthcare companies have invested in R&D to produce 3D-printer devices that deliver drugs according to the treatment plan for every patient.

5) Personalized Surgical Models

3D printers produce three-dimensional objects and models from digital files. The surgeons use 3D printing technologies to produce anatomical models based on the scanned patient data. They create a digital file based on the CT and MRI scans and produce 3D-printed anatomical models using the digital file. At present, 3D-printed anatomical models are used widely by healthcare professionals across the world while planning routine and complex surgeries. They help surgeons to prepare better for complex surgeries. Also, hospitals leverage 3D-printed anatomical models to curtail both time and cost.

6) Accurate Surgical Preplanning

While planning surgical procedures, surgeons cannot evaluate and assess a patient’s anatomy accurately on a computer screen. Many surgeons these days 3D-print anatomical models to gather additional and accurate information during preoperative planning. The 3D-printed anatomical models help surgeons to study and understand the impaired organs elaborately before the operation.

The surgeons can leverage the 3D model to explore various approaches and decide the most appropriate approach during the planning process. Hence, it becomes easier for the surgeon to reduce the operation time while improving the operational outcome. 3D printing technologies will become an integral part of surgical planning in the future.

7) Patient-Specific Prosthetics

As a branch of surgery, prosthetics deal with replacing missing body parts with artificial structures or artificial devices. Prosthetics make it easier for disabled people to live a normal life. But the prosthetists have to put extra time and effort to design prosthetics according to the dimensions measured by them.

3D printing technologies enable prosthetists to produce anatomic prosthetics precisely and accurately using high-quality imaging technologies. A prosthetist can further use a 3D printer to produce patient-specific prosthetics on demand. Many market analysts believe that 3D printing technologies will make prosthetics affordable for millions of disabled people in the future.

8) Driving Medical Research and Development

3D printing technology is transforming medicine and surgery by facilitating medical research and development (R&D). Many doctors and researchers these days use 3D printers to develop new treatments for various diseases by producing automated cell structures. The automated cell structures make it easier for physicians and surgeons to determine if a new drug is toxic to humans and animals during preclinical trials. Also, 3D printing technologies enable researchers to develop new clinical solutions, create innovative devices, and personalize various treatments without investing in extra time and effort.

3D

printing is one of the disruptive technologies that are transforming

the healthcare industry. In addition to leveraging 3D printing

technologies, most healthcare industries these days invest in R&D.

The combination of demand and research will create many new 3D printing

applications in medicine and surgery in the near future.

Keyword: 3D printing applications in medicine

References:

httpa://Formlabs.com/asia/blog/3d-printing-in-medicine-healthcare/

https://www.marketdataforecast.com/market-reports/3d-printing-healthcare-market

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6139809/

https://www.think3d.in/wp-content/uploads/2018/07/Surgery-Planning-Case-Study.pdf

https://www.researchgate.net/publication/327320182_The_clinical_use_of_3D_printing_in_surgery

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4875895/

https://www.sculpteo.com/en/3d-learning-hub/applications-of-3d-printing/medical-3d-printing/

https://formlabs.com/asia/blog/3d-printing-in-medicine-healthcare/

https://www.science.org.au/curious/people-medicine/bioprinting