Additive manufacturing/3D printing is

one of the fundamental technologies driving Industry 4.0. Enterprises

leverage various 3D printing technologies to transit from Industry 3.0

to Industry 4.0. But some of these 3D printing technologies are used

widely by both individuals and enterprises.

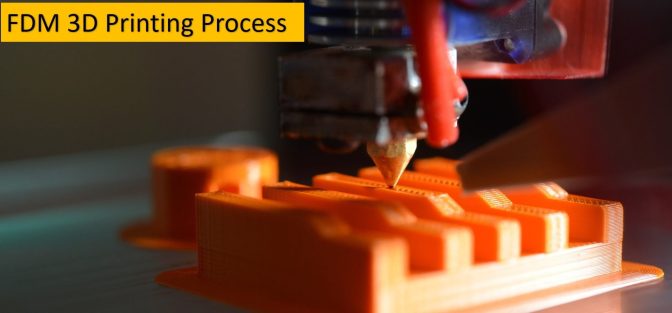

Fused Deposition Modeling (FDM)

is one of the 3D printing technologies that are popular with companies,

startups, engineers, students, and hobbyists. In addition to being

easy-to-use and budget-friendly, FDM 3D printing technology allows you

to choose many materials and reuse the filaments.

You can use an FDM 3D printer to convert computer-aided design (CAD) files into solid three-dimensional parts. The machine will create the part by depositing thermoplastic filament onto a print bed layer by layer. But you must remember that FDM 3D printing is a multistep process.

You can customize and streamline the 3D printing process only by choosing the right printer, model material, and support material. Also, you need to convert the CAD file into an STL file. After completing the preliminary tasks, you have to monitor the FDM 3D printing process and perform post-processing activities to produce a part that meets your precise project needs and preset quality standards.

How to Plan and Improve the FDM SLS 3D Printing Process?

Select the Right FDM 3D Printer

Based on your predefined project needs, you have the option to choose from several types of FDM 3D printers. The FDM 3D printing machines differ from each other primarily in two aspects –mechanical nature and operational coordinate system. Hence, you need to compare the FDM 3D printers manufactured by different companies.

Combine the Right Modeling and Support Material

While planning the FDM 3D printing process, you must focus on choosing the right modeling and support materials. The modeling material will form a solid three-dimensional object, while the support material will provide support to the part as it is 3D printed.

You have the option to choose from a variety of modeling materials – ABS, PLA, PET, Nylon, PC, and TPU (flexible). Some of these materials are pure polymer, while others are composites.

Hence, they differ from each other in many aspects – printability, layer adhesion, heat resistance, impact resistance, and stress resistance. In addition to choosing the right modeling material, you must complement it with the appropriate support material.

Convert the CAD File into STL File

FDM 3D printer will produce the part based on a digital 3D model. But you have to convey information to the printer in the form of an STL file. You have to convert the CAD file into an STL file to provide information to the printer in the standard data transmission format.

Set Print or Process Parameters

FDM 3D printers allow you to set various print parameters or process parameters – layer height, build speed, nozzle temperature, build platform temperature, and cooling fan speed. You must decide the build volume and layer height according to the size of the part to be 3D-printed.

The desktop 3D printers support smaller build volumes than industrial 3D printers. If you are using a desktop 3D printer, you have to divide the large parts into smaller parts according to the build volume supported by the machine.

You can create the large part by assembling the small parts after the 3D printing process. However, you can customize the FDM 3D printing process according to precise project needs by setting or adjusting these parameters.

Start the FDM Printing Process

You have to start the FDM 3D printing process by loading the thermoplastic material into the 3D printer. The FDM 3D printer will feed the filament as threads and extrude the melted filament through extrusion nozzles.

Most FDM 3D printers feature extrusion nozzles that deposit the melted filament in both horizontal and vertical ways. The FDM 3D printer will function according to the parameters set by you. Also, it will refer to the STL file to deposit the filament in the right physical dimensions.

The melted filament will cool and solidify gradually after being deposited onto the build platform. But you can reduce the cooling time using fans attached to the extrusion head.

Remove or Separate the Support Material

Once the FDM 3D printing process is over, you have to focus on improving the surface finish by removing or separating the support accurately. You have the option to choose from two distinct support removal methods – standard and dissolvable.

You can remove the support material quickly and effortlessly by opting for the standard method. The method requires you to remove support material by cleaning the surface. However, you have to use needle-nose pliers and dental picks to remove the support material from holes, hollows, and other hard-to-reach places.

You can opt for the dissolvable method when the support material is soluble. This method requires you to remove the support material using the appropriate solvent. You need to keep the 3D-printed part in a bath till the support material is dissolved and separated. However, you must remember that each of these support removal techniques has its pros and cons.

Perform Post-Processing Activities

After removing the support material, you need to improve the 3D-printed part’s look, feel, and finish by performing a variety of post-processing activities – polishing, sanding, priming and painting, gap filling, cold welding, dipping, metal plating, and epoxy coating.

But you must remember that the post-processing activities vary according to the nature and requirements of the 3D-printed part. Hence, you have to combine the post-processing activities according to the 3D-printed part. At the same time, you must perform every post-processing activity accurately and efficiently using the appropriate toolkit.

Conclusion

FDM 3D printing technologies create opportunities for you to produce a variety of parts without putting in extra time and effort. You must focus on customizing the FDM 3D printing process according to the precise needs of each project. At the same time, it is important to improve the dimensional accuracy and print quality by implementing a slew of FDM 3D printing best practices.

However, you can save both time and resources by availing of professional FDM 3D printing services. The leading 3D printing companies use advanced 3D printers and allow you to choose from a variety of filaments. Also, you can customize the FDM 3D printing process by sharing important information related to the part or product required for your upcoming project.

About Aurum3D

We are amongst the major 3D printing service providers in Bangalore, India. We have been providing custom SLA, SLS and FDM 3D printing services to many major industries. Please feel free to get in touch with us for your custom needs, our 3D printing solutions experts will get back to you within one business day.

References

https://all3dp.com/2/cartesian-3d-printer-delta-scara-belt-corexy-polar/

https://www.hubs.com/knowledge-base/fdm-3d-printing-materials-compared/

https://smc-fluidcontrol.com/cooling-systems-in-3d-printing/

https://www.hubs.com/knowledge-base/post-processing-fdm-printed-parts/#support