3D printing or additive manufacturing is one of the next-generation technologies transforming the global automotive industry.Companies and startups in the automotive industry use 3D printing machines and materials to simplify many time-consuming and cost-intensive processes.

In addition to switching from subtractive manufacturing to additive manufacturing, various 3D printing technologies enable automotive companies to modernize the designing, prototyping, testing, production, and maintenance of motor vehicles.

Most automotive companies these days save resources by 3D-printing end parts instead of producing parts and components. Likewise, many companies have already started selling 3D-printed cars and supercars in high-income countries.

In 2022, India emerged as the fourth-largest automotive market in the world. At present, Bangalore is home to many international automotive and automobile companies. The automotive companies in Bangalore leverage 3D printing technologies to become a part of Industry 4.0.

Some of these companies have built in-house 3D printing infrastructure, while others outsource 3D designing and 3D printing services. Many 3D printing companies have built a reputation by designing and printing parts for leading automotive companies.

Hence, every automotive company now has the option to choose from many automotive 3D printing companies in Bangalore. We are making it easier for you to get superior and customized automotive 3D printing solutions in Bangalore by comparing some of these reputable companies and startups.

Shortlisting 7 of the Best Automotive 3D Printing Companies in Bangalore

1. Aurum3D

Aurum3D is one of the local automotive 3D printing companies in Bangalore. But it has built a reputation by providing online 3D designing and 3D printing services to automotive companies across regions. The automotive 3D printing services provided by Aurum3D help manufacturers launch superior motor vehicles by accelerating prototyping, customization, and production.

Also, many automotive companies partner with Aurum3D to supply parts or components to customers on demand by getting FDM, SLS, or SLA 3D printing services. Aurum3D has been impressing automotive companies by reducing component weight, producing parts for vintage motor vehicles, and supplying spare parts on demand.

2. Rapidproto Labs

This 3D printing company's factory and office are located in Tamil Nadu. But Rapidproto Labs has been providing online 3D printing services to automotive companies in Bangalore. It has produced parts for automotive companies using FDM, SLS, and SLA 3D printing technologies.

Rapid3D delivers parts and conceptual models to clients in about 2 days. Hence, it becomes easier for automotive companies to validate and refine prototypes regularly. At the same time, the delivery time helps automotive companies to supply parts or components to customers on demand.

3. Think3D

The factory and corporate office of Think3D are located in Hyderabad. But Think3D has been providing 3D designing and 3D printing services to automotive companies in Bangalore through its website. Many automotive companies in Bangalore partner with Think3D to leverage its robust infrastructure consisting of 69 in-house machines.

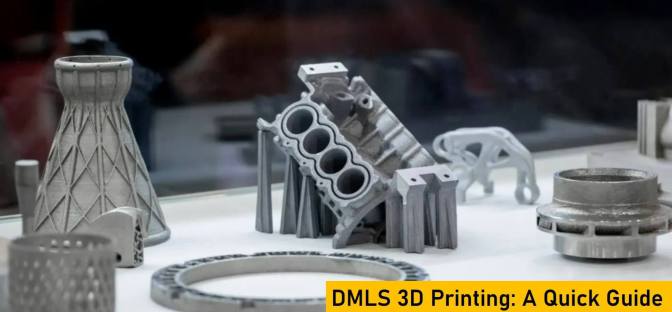

Think3D meets the automotive 3D printing needs of clients using FDM, SLS, SLA, DMLS, and MJP 3D printing machines. In addition to deploying technically-qualified teams, Think3D focuses extensively on protecting customers’ designs and data. The company has produced fixtures, tooling, and spare parts for leading automotive companies in Bangalore.

4. 3Ding

This Bangalore-based 3D printing company meets the additive manufacturing needs of automotive companies in two district ways. 3Ding enables automotive companies in Bangalore to produce parts and components on their own by renting the right 3D printing machines.

Also, automotive companies in Bangalore have the option to avail themselves of the 3D designing and 3D printing services provided by 3Ding. Many automotive companies choose 3Ding to produce parts and prototypes in-house without escalating 3D printing costs.

5. Precious3D

This Chennai-based company has been providing online 3D printing services to companies from many sectors including automotive. Precious3D has produced parts for automotive companies using FDM, SLS, and SLA 3D printing technologies.

In addition to improving 3D printing quality consistently, Precious3D focuses on reducing 3D printing time and costs. Leading automotive companies in Bangalore partner with Precious3D to produce automobile parts for shop floors on demand.

6.Wipro3D

Its state-of-the-art manufacturing facilities differentiate Wipro3D from other automotive 3D printing companies in Bangalore. The Bangalore-based company has been providing 3D designing, printing, and post-processing services to many automotive companies. Also, it delivers superior parts and components through a comprehensive test and validation process.

Wipro3D aims to make metal 3D printing machines and materials affordable and accessible for companies in various sectors, including automotive and automobile. It makes it easier for automotive companies to create conceptual models and product prototypes by offering additive consultation services.

7. Makenica

This 3D printing company has offices in several locations in Bangalore. Makenica has been providing plastic and metal 3D printing companies to automotive companies through its website. Automotive companies have the option to choose from a wide range of 3D printing machines and materials – FDM, SLS, SLA, MJF, PolyJet, and metal.

Makenica ensures the dimensional accuracy of 3D-printed parts by keeping in place a five-step quality-checking process. It further focuses extensively on keeping customers’ designs and data safe. Automotive companies in Bangalore partner with Makenica to get parts produced using a network of over 2000 3D printing machines.

Conclusion

While outsourcing 3D designing or 3D printing activities, your company has the option to choose from many automotive 3D printing companies in Bangalore. Each company allows you to choose from a wide range of 3D printing technologies and manufacturers.

But you should remember that these companies provide online automotive 3D printing company. Hence, you can partner with one of the best automotive 3D printing companies in Bangalore regardless of the location of their 3D printing facilities.