At present, Selective Laser Sintering

(SLS) is one of the widely used 3D printing technologies. Enterprises

from various sectors use SLS 3D printing technology

to produce parts and prototypes with superior strength, stiffness,

resolution, and mechanic properties. Also, they have the option to

choose from a variety of powdered materials according to precise project

needs.

A market

analysis report published by Grand View Report suggests a steady

increase in the shipment of SLS 3D printers. However, SLS, like other

popular 3D printing technologies, has been evolving consistently. We can

understand and analyze the evolution of SLS 3D printing based on the

technology’s history, materials, use cases, and popularity.

As a Patented 3D Printing Technology

SLS

3D printing technology was developed with the aim to replace liquid

materials with powdered materials. Dr. Carl Deckarddeveloped the

technology at the University of Texas. He patented the technology in

1988. In 2006, a startup company founded by Dr. Deckard and his academic

adviser Dr. Joe Beaman started building and shipping SLS 3D printers

commercially. The patent related to SLS 3D printing technology expired

in 2014.

As a Non-Patented 3D Printing Technology

SLS became an open-source 3D printing technology after the expiration of the recent patent. Also, the expiration of the recent patent creates opportunities for many companies to build and ship low-cost and compact SLS machines. Many hardware manufacturers these days leverage OpenSLS as an open-source and low-cost platform to build multiple variants of SLS 3D printers. Hence, enterprises and individuals these days have the option to choose from many compact and large SLS 3D printers.

As a Widely Used Industrial 3D Printing Technology

While creating parts and prototypes for industrial projects, many enterprises these days prefer SLS to other widely-used 3D printing technology. Engineers find it easier to produce parts with enhanced strength, dimensional accuracy, and resolution using SLS 3D printers. Also, they love the option to choose from a wide range of powdered materials and filaments according to precise project needs while using SLS 3D printers.

That is why; SLS 3D printing is used widely by enterprises to produce strong and stiff parts with fantastic mechanical properties. The absence of a support structure speeds up the printing process by eliminating many post-processing activities. Also, engineers can leverage the no need for support to produce robust and detailed parts in a short amount of time. SLS 3D printing further curtails overall 3D printing costs by facilitating material recycling and reducing material wastage.

A Wide Range of SLS Materials and Filaments

Unlike other 3D printing technologies, SLS forms parts and prototypes by sintering small particles of powdered materials using a high-power laser. The industrial SLS 3D printers initially produced objects using nylon. Nylon is one of the widely-used engineering thermoplastics. In addition to being strong, durable, and lightweight, nylon facilitates the printing of items that can resist the impact of heat, chemicals, water, dirt, and UV ray.

That is why; engineers still opt for nylon while creating parts and prototypes using SLS 3D printers. But manufacturers have been developing and launching new SLS 3D printing materials regularly. Engineers, at present, have the option to choose from a wide range of nylon-based composite materials and high-performance materials. For instance, they can boost the quality of printed parts or prototypes using composite materials formed by mixing nylon with aluminum, carbon fiber, and glass fiber.

The composition enables them to enhance the thermal and mechanical properties of the material. At the same time, engineers can also choose from a slew of high-performance materials – PEEK, PEKK, flexible TPUs, anti-static polymers, and flame-retardant polymers. The emergence of innovative and superior materials contributes hugely toward making SLS a widely-used industrial additive manufacturing technology.

Common and Innovative Applications

Based on the precise needs of a part or prototype, engineers have the option to choose from a wide range of SLS 3D printing machines and materials. Hence, enterprises from various sectors create new use cases of SLS 3D printing regularly. We can summarize the evolution of SLS 3D printing based on some use cases or applications.

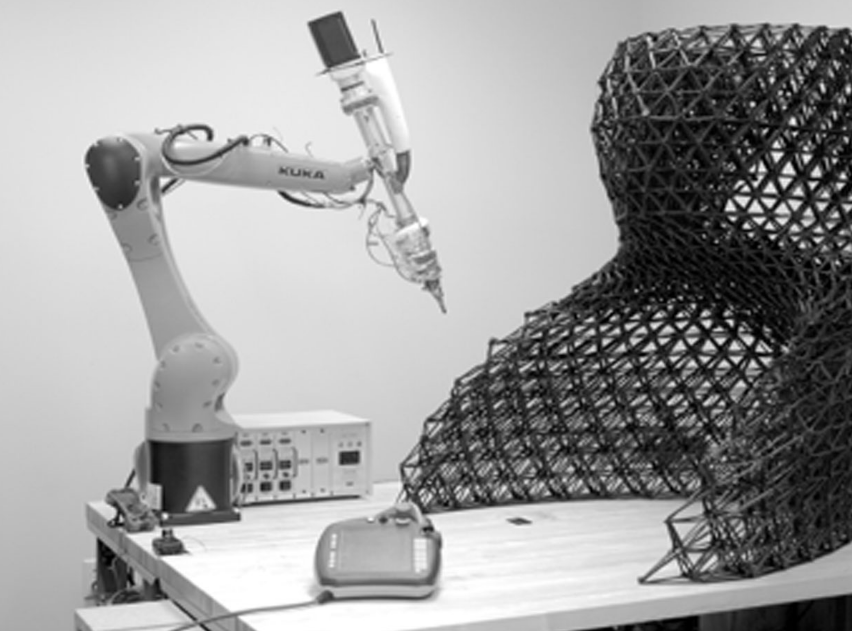

Complex Parts Manufacturing

Engineers these days design parts with intricate designs and complex geometries digitally. SLS 3D printing technology makes it easier for engineers to convert digital designs into solid parts or prototypes. Also, engineers can leverage SLS 3D printing to boost a product or process through part consolidation.

Low Volume Production

As mentioned earlier, SLS is a fast and cost-efficient 3D printing technology. It reduces overall printing costs by reducing material wastage. Likewise, it speeds up the printing process by eliminating support structures. Hence, it becomes easier for enterprises to facilitate low-volume productions of parts, tools, and fixtures.

Mass Customization

Manufacturing companies use SLS 3D printers for both small-batch manufacturing and end-use production. The technology further makes it easier for them to customize consumer products on a mass scale without escalating costs. The engineers can perform mass customization of products simply by making relevant changes to the digital 3D model.

Rapid Prototyping

While evaluating an idea or concept, engineers need to fabricate a physical part or model rapidly and repeatedly. SLS 3D printers help engineers to produce prototypes rapidly. The engineers can further refine the prototype by making changes to the digital 3D model or experimenting with new materials.

Material Experimentation

The new-generation SLS 3D printers create opportunities for engineers to experiment with a variety of powdered materials. In addition to using composite materials, engineers can choose materials with superior thermal and mechanical properties. Hence, they can produce innovative parts according to changing project needs.

Conclusion

At

present, SLS is a widely used industrial 3D printing technology. But

SLS is one of the additive manufacturing technologies that have been

evolving consistently. Both individuals and enterprises these days have

the option to choose from a wide range of SLS 3D printers and printing

materials. The ongoing advancements contribute immensely towards

boosting the adoption and popularity of SLS 3D printing.

Source - https://medium.com/@allaboutappsbiz/the-evolution-of-sls-3d-printing-24bc6df91aad