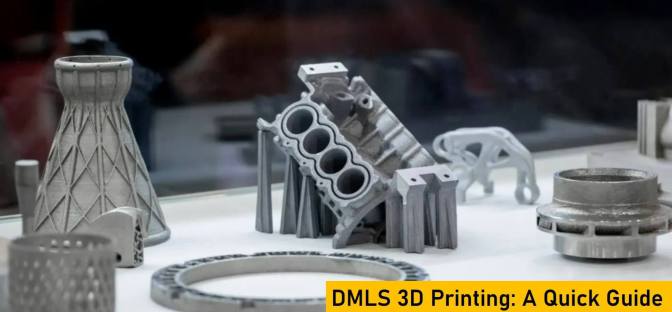

A 3D printer produces physical

three-dimensional objects from three-dimensional digital models. But 3D

printing machines are driven by several 3D printing technologies. The

usage statistics posted on Statista suggest that Fused Deposition Modeling (FDM) currently has a much larger installation base than other 3D printing technologies.

Also,

FDM is one of the additive manufacturing technologies that are used

widely by individuals and enterprises. Students, innovators, and

hobbyists opt for FDM as a beginner-friendly and cost-effective 3D printing technology.

At the same time, industrial-grade FDM 3D printers help enterprises

replace subtractive manufacturing with additive manufacturing.

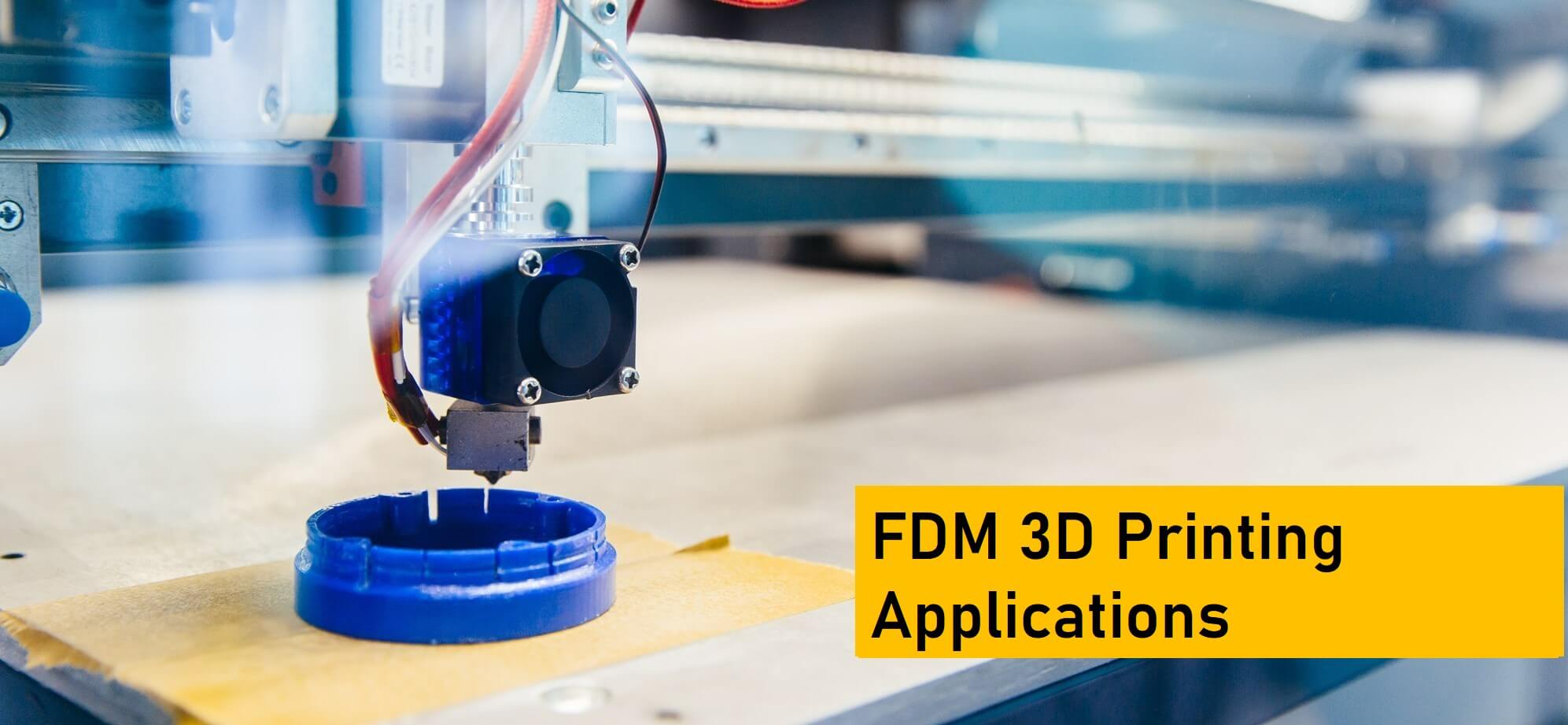

Unlike other 3D printing technologies,

FDM produces parts using the material extrusion technique. Users have

the option to choose from a wide range of production-grade

thermoplastics according to the nature and requirements of individual

parts. Hence, they have can produce a variety of parts by combining the

right FDM 3D printing machines and filaments.

Both

individuals and enterprises create new FDM 3D printing applications

regularly. Also, they use advanced FDM 3D printing machines and

experiment with innovative FDM 3D printing materials. We can understand

some of the major FDM 3D printing applications based on use cases

created by individuals and enterprises across industries and regions.

Industrial Applications of FDM 3D Printing

Getting Ready for Industry 4.0

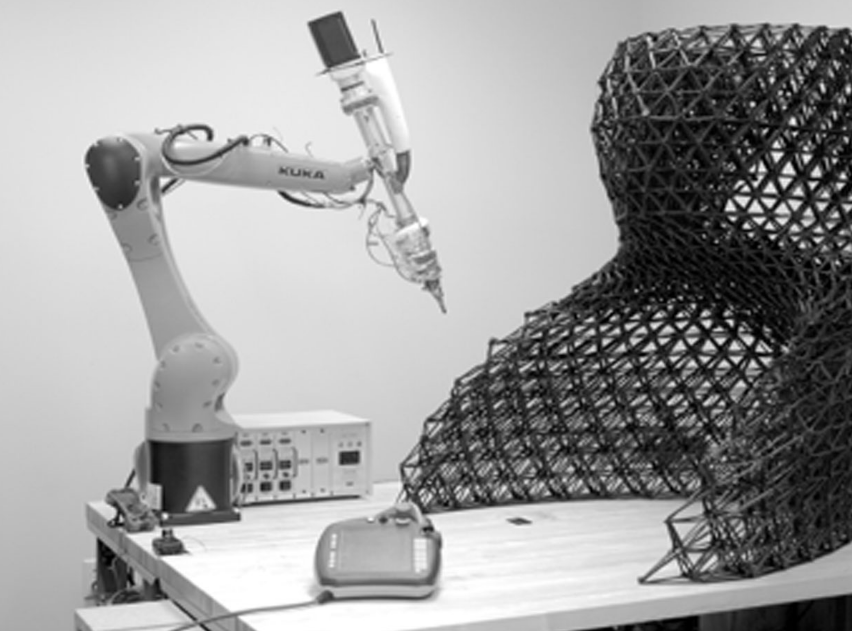

Enterprises

have been switching from subtractive manufacturing to additive

manufacturing to become a part of Industry 4.0. But they look for

technologies effective in reducing production time and costs. FDM is a

simple and cost-effective 3D printing technology.

Enterprises have the option to choose from a wide range of FDM 3D printing machines and materials. Also, they can reduce upfront investment by availing of professional FDM 3D printing services. Hence, manufacturers leverage FDM 3D printing to get ready for Industry 4.0.

Rapid Prototyping

Large companies invest in R&D to outperform competitors by coming up with unique ideas. Researchers evaluate the next best idea elaborately by making prototypes. In addition to reducing production time, prototypes help engineers identify and prevent potential problems. Researchers find it easier to create prototypes from digital files using FDM 3D printers. Also, they use the printer to create multiple versions of the prototype without increasing time and cost.

Testing Design Ideas

Automobile and aerospace companies these days boost user experience by producing innovative parts and customizing existing parts. They invest in FDM 3D printing machines and materials to test new design ideas without escalating project costs. Researchers can use an FDM 3D printer to evaluate new design ideas ad alter existing designs without delaying product launch.

Producing Replacement Parts

No automobile company can impress and attract customers without providing outstanding customer service. Also, it cannot deliver outstanding customer service without ensuring fast and reliable delivery of spare parts. Leading companies have already transformed spare part management using 3D printing technologies.

They invest in FDM 3D printing to reduce the time and resources required to produce replacement parts for individual customers. Hence, many companies these days print spare parts instead of maintaining an inventory of spare parts.

Low-Volume Manufacturing

Companies opt for low-volume manufacturing to reduce time to market and identify potential market risks. But no company can produce a lower number of parts using conventional manufacturing technologies. 3D printing technologies like FDM make it easier for companies to scale up or scale down the production of parts on demand.

Engineers use FDM 3D printers to drive low-volume production without investing in expensive tooling and additional materials. The printers create opportunities for them to experiment with different thermoplastic filaments while reducing material wastage. Also, engineers can change a part simply by altering the digital 3D model.

Creating Pre-Surgical Models

Pre-surgical models help surgeons reduce the risk of complications using the right instruments. Hence, surgeons develop patient-specific surgical models as part of pre-surgical planning. FDM 3D printers make it easier for surgeons to develop patient-specific surgical models that replicate specific organs of a patient exactly.

Producing Functional Prosthetics

The conventional manufacturing techniques make the production of functional prosthetics complicated and expensive. But medical practitioners find it easier to produce functional prosthetics for individual patients using FDM 3D printers. In addition to supporting personalization, FDM 3D printing makes prosthetic lambs affordable for a large number of people.

Non-Industrial Applications of FDM 3D Printing

Promoting Experimental Learning

Many schools, colleges, and universities these days invest in FDM 3D printers to promote experimental learning. Students use FDM 3D printers to visualize concepts and create models while mastering one of the important next-generation technologies. Recently, students surprised everyone by building, testing, and finetuning DIY drones using FDM 3D printing.

Personalizing and Customizing Gifts

FDM 3D printer helps enthusiasts and innovators unleash their creativity. Many people these days use FDM 3D printers to produce customized gifts for friends. They make the gift items like mobile covers, planters, key chains, and lamps look unique by designing their own digital 3D models or redesigning existing 3D models.

Replacing Household Items

Homeowners found it difficult to purchase and replace household items during the COVID-19 lockdowns and shutdowns. Many people use FDM 3D printers to produce household items during the pandemic. They use FDM printers to replace clips, buttons, hooks, showerheads, and other household items while working from home.

Changing Home Décor Styles

Many homeowners these days impress guests by changing home décor style as the season changes. FDM 3D printing machines help homeowners create unique and customized pieces on their own. Many homeowners these days use FDM 3D printers to produce beautiful home décor before the season changes.

Conclusion

In addition to being the most commonly used 3D printing technology, FDM has been evolving consistently. For instance, users nowadays have the option to choose from conventional and cloud-based FDM 3D printers. Likewise, they can experiment with many classic and innovative 3D printing materials.

Professional FDM 3D printing services create opportunities for individuals and enterprises to produce parts using the desired printing machine and filament. Hence, FDM 3D printing applications will continue to evolve in the future. The new use cases will keep the popularity of FDM intact while overcoming the major shortcomings of this 3D printing technology.