3D printing technologies enable

enterprises from various industries to produce production parts and

functional prototypes without investing in extra resources. But

engineers have to use specific materials according to their choice of 3D printing technologies.

Direct Metal Laser Sintering enables manufacturers to produce spare

parts and prototypes using a variety of metals and metal alloys.

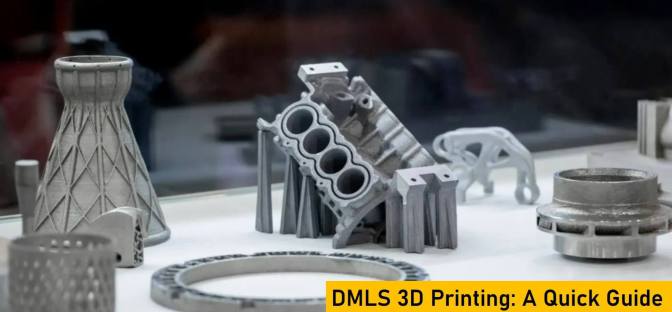

What is DMLS 3D Printing?

According to ScienceDirect, “Direct Metal Laser Sintering (DMLS) is an AM technique for metal 3D printing. In this process, the metal powder (20 μm diameter), free of binder or fluxing agent, is completely melted by the scanning of a high-power laser beam. The resulting part has properties like the original material.”

DMLS is an industrial 3D printing technology. It belongs to the category of power bed fusion category of additive manufacturing technologies. It produces parts by melting metal powders or metal alloy powders completely using a high-power laser beam.

DMLS creates opportunities for engineers to print strong and durable functional parts using a wide range of metal powders and metal alloy powders.The metal powders differentiate DMLS from other 3D printing technologies.

What Metal Powders are used in DMLS 3D Printing Process?

While planning a DMLS 3D printing project, engineers have the option to choose from a variety of metal and metal alloy powders. They can choose from aluminum, stainless steel, titanium, cobalt chrome, or managing steel.

The metal material options make it engineers to produce parts using the appropriate metal. For instance, an engineer can create parts effective in resisting acid and corrosion by choosing stainless steel. At the same time, she can opt for aluminum to produce metal parts effective in resisting stress.

How Does DMLS 3D Printing Work?

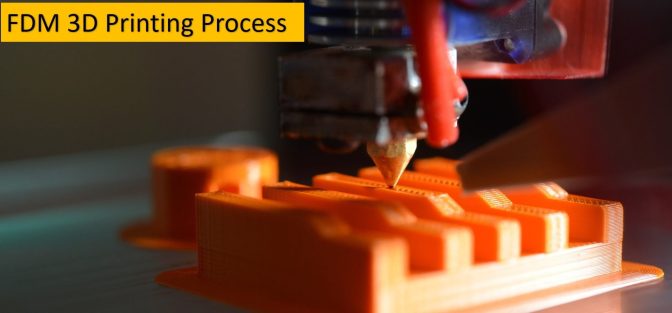

Like other 3D printing technologies, DMLS printers create parts layer by layer based on digital 3D files. Engineers refine the digital 3D model using appropriate software to generate code that can be understood by the metal 3D printer. After preparing the digital 3D file, engineers fill the DMLS printer hopper with a specific metal or metal alloy powder.

The printer uses heaters to bring the metal powder up to the sintering range of the metal allow. It subsequently starts dispensing thin layers of the metal powder onto the build platform. The high-power laser form solid structures by sintering the metal powder selectively. The DMLS 3D printer continues dispensing and sintering the metal powder till the part is produced completely.

Once the physical printing process is over, engineers allow the part to cool fully. They remove the loose metal powder from the DMLS printer as well as remove the support before starting post-processing activities. They refine and treat the 3D-printed part by performing activities like surface finishing, machining, and heat treatment. DMLS 3D printing technology delivers metal parts in about 7 to 10 days.

What are the Common Applications/Use Cases of DMLS 3D Printing Technology?

Replacing Conventional Metalworking Technologies

Conventional metalworking technologies are not effective in producing parts with complex geometries. Many manufacturers invest in DMLS 3D printers to print complex parts directly using high-performance metals and metal alloys.

Producing Strong and Lightweight Parts

DMLS 3D printing machines produce single-component metals by melting metal powders completely. The single-component metal is effective in producing parts and prototypes that are strong, durable, and lightweight. Engineers can easily reduce the strength or weight of a spare part using the appropriate metal powder.

Improving Part’s Functional Performance

While using subtractive manufacturing methods, engineers have to focus extensively on manufactur ability. The focus on manufactur ability impacts the spare part’s functional performance negatively. DMLS 3D printing enables engineers to focus on improving a part’s functional performance instead of manufactur ability.

Reducing Part Count

At present, DMLS is used widely by companies in the aerospace and automotive industries. These companies leverage this 3D printing technologies for a variety of purposes, including weight reduction, complex part production, and mass customization. At the same time, DMLS creates opportunities for them to reduce the number of parts through integration and optimization.

Facilitating Customization and Personalization

Companies in the medicine and healthcare industries use DMLS 3D printing to produce bridges, crowns, and prosthetics. DMLS 3D printers create opportunities for medical practitioners to create custom prosthetics for individual patients. At the same time, they can use high-strength metals to produce prosthetics that patients can use over a longer period of time.

Providing Freedom of Design

DMLS, like other powder bed 3D printing technologies, provides freedom of design to engineers. As engineers are not required to use multiple tools and fixtures, they can produce new parts by experimenting with complex designs and innovative design rules. Also, they can customize existing designs and models to boost the functional performance of various parts.

What are the Pros and Cons of DMLS 3D Printing?

Pros

- Direct metal printing keeps the mechanical properties of the metal intact.

- Engineers can choose from a wide range of metals and metal alloys.

- Engineers can produce strong and durable metal parts without using additional tooling and fixture.

- Metal powders help engineers produce parts with dimensional accuracy and complex geometries.

- Options to produce parts with a smoother finish using finer metal powder.

- Manufacturers can control 3D printing costs by reusing metal powders.

Cons

- One of the complex industrial 3D printing technologies.

- Not popular with students and hobbyists due to the high cost of DMLS 3D printing machines and materials.

- Does not support large build volumes like other industrial 3D printing technologies.

- Engineers can produce parts and prototypes in weeks using this slow additive manufacturing technology.

Please read our blog “DMLS Advantages and Disadvantages” to know the pros and cons of this industrial 3D printing technology in detail.

Conclusion

Unlike other 3D printing technologies, DMLS facilitates the production of metal parts and prototypes. At present, DMLS 3D printing technology is used widely by enterprises from various industries. But the industrial 3D printing technology has its pros and cons. Leading 3D printing service providers overcome the limitation of DMLS 3D printing by monitoring the printing process and adopting several best practices.

References

https://www.sciencedirect.com/topics/materials-science/direct-metal-laser-sintering

https://www.protolabs.co.uk/services/3d-printing/direct-metal-laser-sintering/

https://all3dp.com/2/direct-metal-laser-sintering-dmls-simply-explained/

https://www.rapiddmls.com/what-is-dmls/