Enterprises from various industries have

been switching from subtractive manufacturing to additive manufacturing

to curtail production time and cost significantly. As its name

indicates, additive manufacturing or additive layer manufacturing

produces a variety of three-dimensional objects physically by adding

materials layer by layer through a computer-controlled process.

According

to AdditiveManufacturing.media, “’ Additive manufacturing’ (AM)

describes the use of 3D printing to make functional components,

including tools and end-use production parts. Unlike ‘subtractive

manufacturing’ such as processes machining, where parts are created by

removing material, additive manufacturing builds geometries by ‘adding’

feedstock such as filament, wire or powder.” Additive manufacturing

produces solid parts, models, prototypes, and products by leveraging 3D

printing. 3D printing technologies produce various objects from

three-dimensional digital models by adding materials or filaments layer

by layer. In addition to reducing material consumption and wastage,

additive manufacturing enables you to produce parts with complex

geometries and varying shapes.

You

also have the option to choose from different types of additive

manufacturing according to the precise project needs. Likewise, you can

use additive manufacturing technologies to produce objects using a

variety of materials – powder, resins, and plastics. That is why; you

should understand and compare some of the widely used additive

manufacturing technologies to streamline the manufacturing process.

Brief Overview of 7 Widely Used Additive Manufacturing Technologies

1. Binder Jetting:

Binder

jetting technique creates parts by joining powder material using a

binder or binding liquid during the fusion process. You have to choose

the appropriate binder or binding liquid according to the type of powder

used in the additive manufacturing process. This type of additive

manufacturing allows you to choose from various types of materials –

ceramics, metal, and polymer. Also, you can make the object appealing by

adding a wide range of colors. But you need to put extra time and

effort into post-processing activities. Also, you cannot use this type

of additive manufacturing to build structural parts with strength and

accuracy.

2. Material Extrusion:

This

popular form of additive manufacturing builds objects by depositing

thermoplastic or composite filament continuously. These industrial 3D

printers are designed with extruding nuzzles through which the

thermoplastic filament is fed. The machine uses heat to fuse the

filament deposited on the build platform layer by layer. Many

enterprises opt for material extrusion as an easy-to-use and

user-friendly additive manufacturing technology. Material extrusion

allows you to build objects using a variety of print materials without

escalating material costs. But this technique requires support. Also, it

is not effective in producing strong and durable parts.

3. Material Jetting:

This

type of additive manufacturing builds three-dimensional objects by

depositing droplets of wax-like materials selectively onto the build

platform. The wax-like material is deposited in layers on top of each

other. The part is formed as the material becomes cool and solid

gradually. The printed object is produced after the support structure is

removed or melted. Enterprises opt for material jetting technology

while producing parts with superior surface finishing and outstanding

accuracy. But wax-like material often makes the printed item fragile.

Also, you do not have the option to choose from a wide range of wax-like

materials for this additive manufacturing process.

4. Powder Bed Fusion:

The

powder bed fusion method builds parts by melting plastic or metal

powder particles using a variety of energy sources. The energy source

melts the powder which is subsequently fused and solidified to create

the pattern. This category of 3D printers is developed with two build

chambers and a creating roller. While using powder bed fusion

technology, you have the option to choose from and combine a variety of

materials. Also, you can 3D-print industrial items with minimal support.

But the additional post-processing increases the additive manufacturing

time significantly. Also, this additive manufacturing technology is

suitable for creating objects with weak structural properties and

varying surface textures.

5. Sheet Lamination :

As

the name indicates, the sheet lamination method produces objects by

stacking and laminating multiple and thin layers of materials using a

variety of ways – bonding, brazing, or ultrasonic welding. You need to

use a CNS or laser cutting machine to form the final shape of the

object. Sheet lamination is one of the fast and cost-efficient additive

manufacturing methods. It enables you to manage materials effortlessly

without providing support structures. But you must arrange a larger

working area and spend additional time on post-processing activities.

You do not have the option to choose from a wide range of materials

while using sheet lamination techniques. You need to use the appropriate

sheet lamination technique to achieve the desired bonding strength.

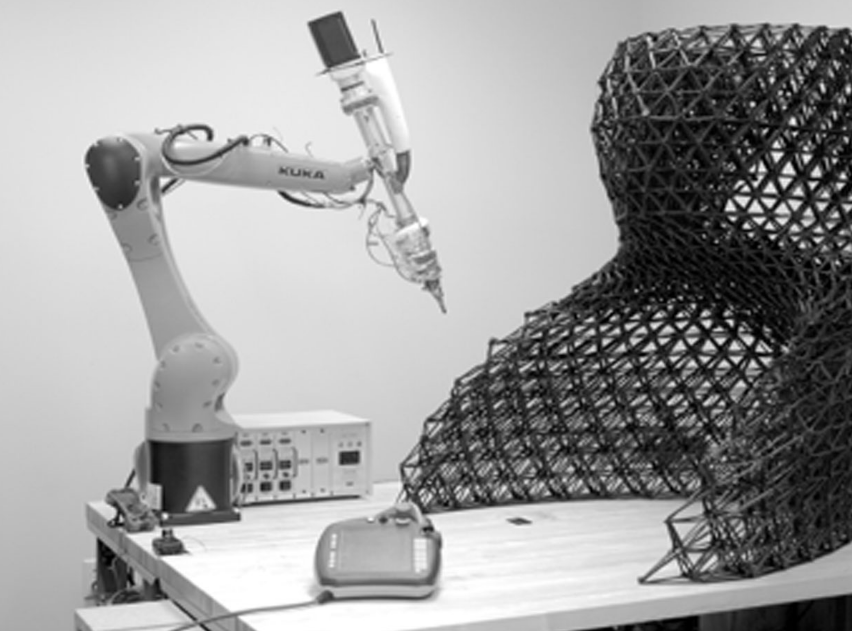

6. Directed Energy Deposition

Direct

energy deposition creates three-dimensional objects by melting

wire-based or powder-based printing material using a variety of energy

sources – laser, plasma arc, and electronic beams. Enterprises these

days use the direct energy deposition method to facilitate hybrid

manufacturing. Also, this type of additive manufacturing is used widely

to create items with complex shapes using metal, ceramic, or polymer. In

addition to accelerating the additive manufacturing process, the direct

energy deposition method is effective in building large, strong, and

dense parts. But you need to incur high capital expenditure to

streamline the additive manufacturing process.

7. Vat Photopolymerization

The

vat photopolymerization method creates three-dimensional items by

converting photopolymer liquid resin into hard plastic. It cures the

photopolymer liquid resin in a vat layer by layer using an ultraviolet

laser. Enterprises opt for this form of additive manufacturing to create

large items with optimal accuracy and superior finish. This method

created parts in a shorter amount of time. But you lack the option to

choose from a variety of photopolymer liquid resins. Also, you have the

put extra time and effort to remove additional resin during the

post-processing. Vat photopolymerization is one of the more expensive

additive manufacturing technologies. While considering and comparing

various types of additive manufacturing, you must not ignore some of the

widely used 3D printing technologies. Both 3D printing and additive

manufacturing technologies build solid objects depositing materials or

filaments layer by layer based on CAD files. But additive manufacturing

technologies are more advanced and rigorous than 3D printing

technologies.

About Aurum3D Aurum3D

is one of the leading 3D printing companies in Bangalore. We have been

working in multiple technologies of 3D printing like FDM, SLA, and SLS 3D Printing in areas like prototyping and custom 3D printing.

References:

https://www.k3syspro.com/advice-centre/erp-advice/whats-the-difference-between-3d-printing-and-additive-manufacturing/

https://www.additivemanufacturing.media/articles/additive-manufacturing-and-3d-printing-are-two-different-things

https://additivemanufacturing.com/basics/

https://www.additivemanufacturing.media/kc/what-is-additive-manufacturing

https://www.appliedengineering.com/blog/2021/1/22/7-types-of-additive-manufacturing

https://blog.spatial.com/types-of-additive-manufacturing

https://www.firetrace.com/fire-protection-blog/additive-manufacturing

No comments:

Post a Comment